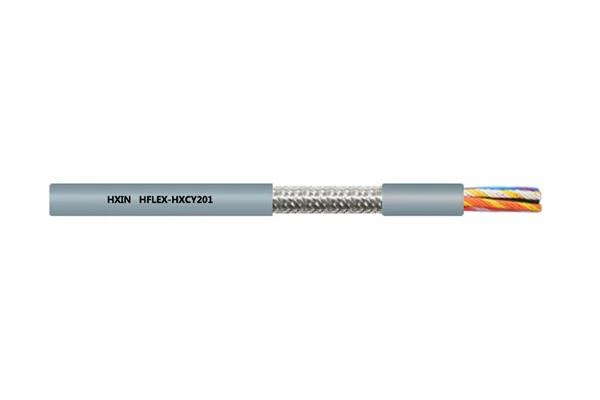

PVC Multi-core Cable

Application

Installation under continuous reciprocation, especially industrial frequent bending environments. such as drag chains of modern machinery and logistics systems, control systems, automatic machinery systems,etc. CNC machines, electronic equipment, hardware ramming, wood and stone machinery, glass and windows machinery, injection molding machinate, robots and manipulators, construction machinery, heavy-duty machinery, automobile manufacturing, lifting transport equipment, automated warehouses, docks, fire engines and other indoor and outdoor shielded environments.

PVC Multi-core Cable | PVC Multicore Flexible Cables |

Product Structure

Conductor | Fine strands of oxygen-free copper wire, according to VDE0295 CLASS 6 standard |

Conductor insulation | High quality mixed PVC |

Conductor colors | Optional |

Core wire structure | Anti twist layered, or grouping with divided gap filling by high strength core |

Inner sheath | PE belt or non-woven belt(optional) |

Shield | Tinned copper mesh braided shield,coverage more than 70% |

Outer jacket material | Special nitrile mixed PVC |

Outer jacket color | Black, Grey, Orange |

Technical Specification

Rate voltage | <0.5mm²:300/300V;≥0.5mm²:300/500V |

Test voltage | 2000V |

Minimum bending radius | Fixed installation: 6×D |

Operating temperature | Fixed installation: -30 to +70℃ |

Flame retardant | Following IEC60332-1-2+EN60332-1-2 |

Oil resistance | See the oil resistance attached list |

Chemical resistance | See the chemical resistance attached list |

Model | Spec | Single strand diameter | Density | OD |

HFLEX-HXCY201 | 0.1*2C | 0.1 | 24 | 4.9 |

HFLEX-HXCY201 | 0.1*3C | 0.1 | 27 | 5.1 |

HFLEX-HXCY201 | 0.1*4C | 0.1 | 32 | 5.4 |

HFLEX-HXCY201 | 0.1*5C | 0.1 | 36 | 5.7 |

HFLEX-HXCY201 | 0.1*6C | 0.1 | 40 | 6.1 |

HFLEX-HXCY201 | 0.1*7C | 0.1 | 45 | 6.5 |

HFLEX-HXCY201 | 0.1*8C | 0.1 | 49 | 6.8 |

HFLEX-HXCY201 | 0.1*9C | 0.1 | 54 | 7.2 |

HFLEX-HXCY201 | 0.1*10C | 0.1 | 62 | 7.7 |

HFLEX-HXCY201 | 0.1*11C | 0.1 | 70 | 8.7 |

HFLEX-HXCY201 | 0.1*12C | 0.1 | 72 | 8.7 |

HFLEX-HXCY201 | 0.1*13C | 0.1 | 77 | 8.9 |

HFLEX-HXCY201 | 0.1*14C | 0.1 | 82 | 9.5 |

HFLEX-HXCY201 | 0.1*15C | 0.1 | 85 | 9.5 |

HFLEX-HXCY201 | 0.1*16C | 0.1 | 88 | 9.5 |

HFLEX-HXCY201 | 0.1*17C | 0.1 | 92 | 9.7 |

HFLEX-HXCY201 | 0.1*18C | 0.1 | 97 | 10.1 |

HFLEX-HXCY201 | 0.1*19C | 0.1 | 101 | 10.5 |

HFLEX-HXCY201 | 0.14*19C | 0.1 | 116 | 11.0 |

HFLEX-HXCY201 | 0.14*20C | 0.1 | 118 | 10.7 |

HFLEX-HXCY201 | 0.2*2C | 0.1 | 27 | 5.2 |

HFLEX-HXCY201 | 0.2*3C | 0.1 | 32 | 5.4 |

HFLEX-HXCY201 | 0.2*4C | 0.1 | 38 | 5.8 |

HFLEX-HXCY201 | 0.2*5C | 0.1 | 44 | 6.1 |

HFLEX-HXCY201 | 0.2*6C | 0.1 | 50 | 6.6 |

HFLEX-HXCY201 | 0.2*7C | 0.1 | 56 | 7.0 |

HFLEX-HXCY201 | 0.2*8C | 0.1 | 65 | 7.6 |

HFLEX-HXCY201 | 0.2*9C | 0.1 | 71 | 8.0 |

Product features

-Water resistance, oil resistance, UV resistance, weather fastness.

-Cold resistance, abrasive resistance, can afford some mechanical force.

-Insulation travel distance: 50m, accelerator 20m/S², moving speed 5m/S.

-Bending lifetime: 30 times/min,>3million times.

-Approvals and standards:ROSH, CE

We are more than happy to manufacture top-of-the-line products for your project. Take a look around our website. If you have a query or you need advice, just contact us. We'll take time to help you.